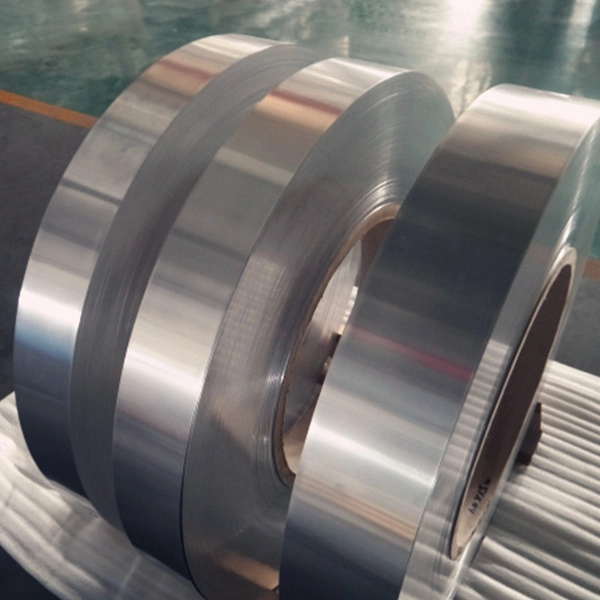

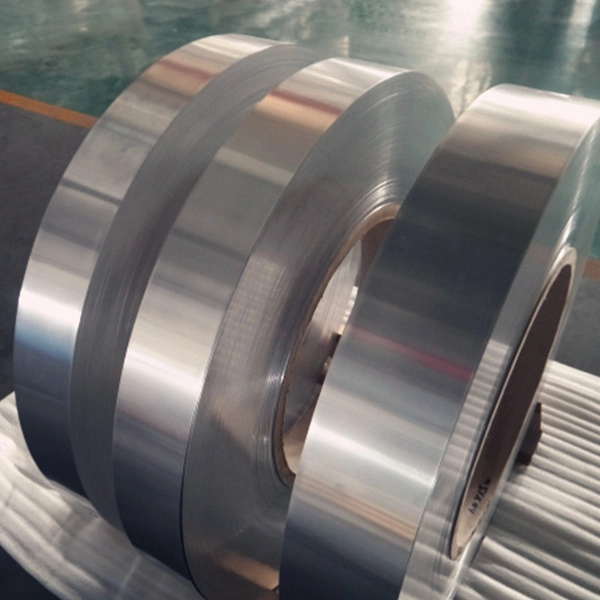

Product Specification

Product | Aluminum Strip |

Property | Anti-corrosion,heat resistant |

Surface | Mill Finish,No Stains,Without Rough Selvedge |

Production Process | Cold Rolled,Hot Rolled |

Internal Diameter | 305mm,405mm,505mm or per request |

Temper | O,H18,H24,H32,H112 Etc;T4,T5,T6,T651 Etc |

Thickness | 0.2mm - 3mm |

Width | 10mm - 600mm |

Payment Term | TT,LC at sight,WestUnion,KunLun Bank |

Package | Export wooden pallets, craft paper, anti-blushing agent. |

Delivery Time | Future goods:20-30 Work days,Ready Stock:7-10 days. |

Quality of Material | Totally free from defects like white rust,roll marks,edge damage,camber,dents,holes,break lines,scratches and free from coil set. |

Kind Attention | Specification can be customized as the customer's requirements. |

The raw materials for the production of aluminum strips are mainly pure aluminum, hot-rolled aluminum coils or aluminum alloy cast-rolled aluminum coils. Longitudinal slitting is performed in the slitting machine, and the aluminum strips of different widths formed after slitting can play their respective roles in actual operations.

There are many classifications of aluminum strips. Common aluminum strip grades are 1050, 1060, 1070, 1100, 3003, 3004, etc. There are also two main states of aluminum strips: soft state and hard state. The soft state is represented by the letter 0. The hard state is represented by the letter H, and a number can be added after the two letters to indicate the degree of softness and hardness or the degree of annealing of the aluminum coil.

Introduction to the classification of aluminum strips

Aluminum strips are widely used in industries such as cables, optical cables, shutters, heaters, and aluminum-plastic composite pipes. Let's take a look at the uses of aluminum strips.

1060 aluminum strip: This type of aluminum strip has high requirements on the corrosion resistance and formability of the working environment, on the contrary, the requirements for strength are not very high. Therefore, 1060 aluminum strip is mostly used in the chemical equipment industry.

1100 aluminum strip: This type of aluminum strip has no rigid requirements for high-strength parts, but requires good corrosion resistance and formability in the processing environment. It is mostly used in the processing of devices and storage containers in the food industry, and the processing of chemical products. Processing, welding parts, heat exchangers, nameplates, reflectors and processing of printing plates, etc., are widely used.

3003 aluminum strip: In this type of aluminum strip, cold-worked bars, cold-worked wires, forgings, foils, heat sinks, etc. are mainly used in parts with high corrosion resistance, good formability and good weldability. , In addition, they can also play a good role in industries such as pressure tanks, heat exchangers, chemical equipment, oil conduits, kitchen equipment, aircraft fuel tanks and reflectors.

3004 aluminum strip: This type of aluminum strip is mostly used in the production and storage device industry of chemical products, the production of lighting parts, the processing and production of cable ducts and sewers, as well as the building baffle and building processing parts industry.

5052 aluminum strip: This aluminum strip has very good formability, erodibility, corrosion resistance, moderate static strength and fatigue strength. Therefore, 5052 aluminum strip is mostly used in aircraft fuel tanks and oil pipe manufacturing, instruments and street lights. Manufacturing of brackets, sheet metal parts manufacturing of transportation vehicles and ships, and manufacturing of hardware products.

Products Application

1. Lighting lighting

2, solar reflector

3, architectural appearance

4, interior decoration: ceiling, wall, etc.

5, furniture, cabinets

6, the elevator

7. Signs, nameplates, cases and bags

8, car interior and exterior decoration

9. Interior decorations: such as photo frames

10, household appliances: refrigerator, microwave oven, audio equipment, etc.

11. Aerospace and military aspects, such as China's large aircraft manufacturing, Shenzhou spacecraft series, satellites and other aspects.

12, mechanical parts processing

13, mold manufacturing

14, chemical/insulation pipeline coating.

15. High quality boar

Aluminum has a density of 2.7 which is about 1/3 that of copper (8.9) or steel (7.8). Low density is very beneficial for the lightweight of ships, vehicles, aerospace vehicles and other vehicles and buildings.

Our Advantage

1.PRODUCTION ADVANTAGES

Integrating steel sales, manufacturing, processing, distribution, and service.

Focused on the aluminum sheet/plate/coil industryfor many years.

Large warehouse supply with largequantity of goods and spot supply.

Various specifications support retaicutting processing customization.

2.DIVERSE EOUIPMENT

Strength certification is trustworthy

Good faith, large business volume, excellentprice.

Wide range of use, qualified product qualityinspection, safe and reliable use.

A COMPREHENSIVE SERVICE SYSTEMThe customer service team is attentive to serving you

Friendly service and timely after-sales service

Supply and delivery speed of goods.

10000 ton inventory quality assurance.

Quality Control

Factory Stocks

If you need our products please write down any questions, we will reply as soon as possible.